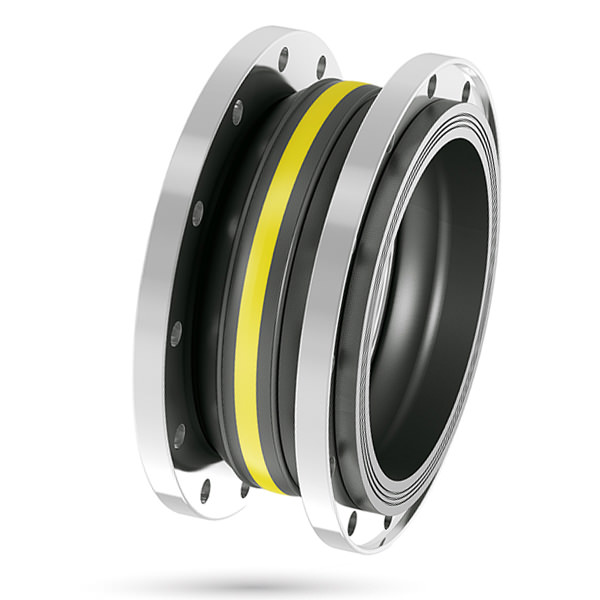

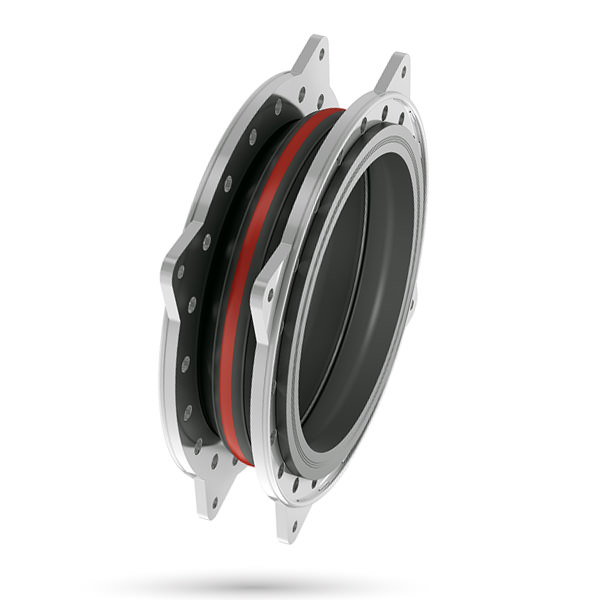

BIKAR designs and manufactures multiple wave expansion joints according to clients needs. These joints are designed to absorb large axial movements while ensuring the safety and efficiency of the piping…

Supply of an important package of expansion joints and dismantling joints for a desalination plant in the United Arab Emirates. This is a tailor-made project for one of the most…

As a company specialized in the design and manufacture of expansion joints, on this occasion we have successfully developed a large expansion joint for a critical customer in Qatar. It…

Supply of expansion joints designed and manufactured for an important pumping station located in Egypt. In this case, due to the movements specified by the client, a type of joint…

As we announced in February, Bikar Expansion Joints was in charge of a project in Bahrain for one of the most important Water and Energy clients in the country, consisting…

Bikar expansion joints makes official the second and last shipment for a desalination plant in Saudi Arabia. In this case it is a project in the extension phase. This project…

Bikar Expansion Joints collaborates with Euskalit in the spread of the European Week of Advanced Management. Our collaborators, called “Astezaleak”, have the mission of promoting these sessions, making visible their…

Sorry, this entry is only available in European Spanish.

As we were already anticipating at the beginning of the year, 2024 is full of news for Bikar Expansion Joints. We are pleased to inform you that we are moving…

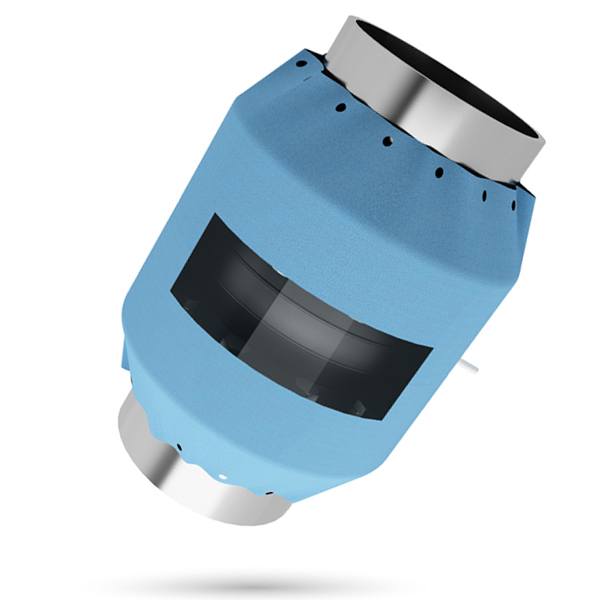

There is no better way to start the year than to present important projects completed and on the way to their destination. In this case it is a project in…