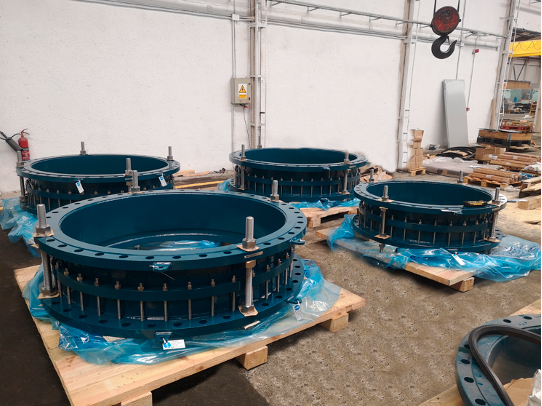

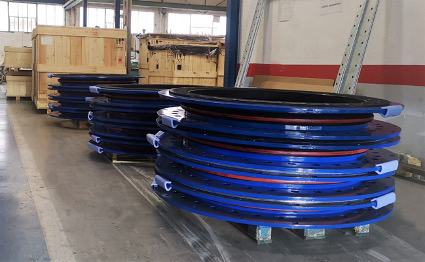

NEW SUPPLY OF HIGH-QUALITY DISMANTLING JOINTS FOR RO PLANT IN MIDDLE EAST

On this occasion, Bikar designed, manufactured, tested and supplied an important set of disassembly joints to be delivered to one of the most important desalination plants in the world, located in the Middle East.

In terms of sizes, the scope of this supply has been from DN1000 to DN1800.

The dismantling joints provided to our client have been both high and low pressure. Both types are custom designed, with special lengths. Likewise, they have inner and outer coatings, certified for potable water.

Due to the aforementioned industry, the supply has been designed with very high quality standards and strict specifications, carried out during the production stages.

Would you like to know more about Dismantling Joints? Check out the various types we have at Bikar through the following link::