Rubber expansion joint package for a water treatment plant in the USA

At BIKAR, a manufacturer with over 40 years of experience and a presence in more than 45 countries, we supplied an expansion joint package for a water treatment plant in…

BIKAR manufactures components, assemblies and equipment for the fluid handling and airtight joint industries.

We develop and manufacture our own products based upon specific needs, taking into account critical factors involving temperature, pressure, and movement. In addition to our consultation and participation in each project’s study, we offer a variety of solutions where quality will always stand out as our strongest mark of identity.

![BF_PPS_TI [TIE RODS]](https://bikarexpansionjoints.com/wp-content/uploads/2016/09/BF_PPS_TI.jpg)

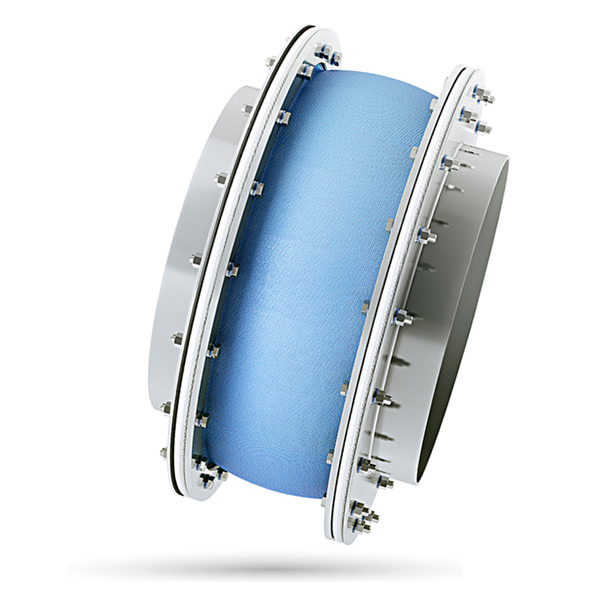

Rubber expansion joints are mainly used to absorb movements, vibrations and forces in piping systems normally, but ot only up to 25 design pressure and 200º C temperature

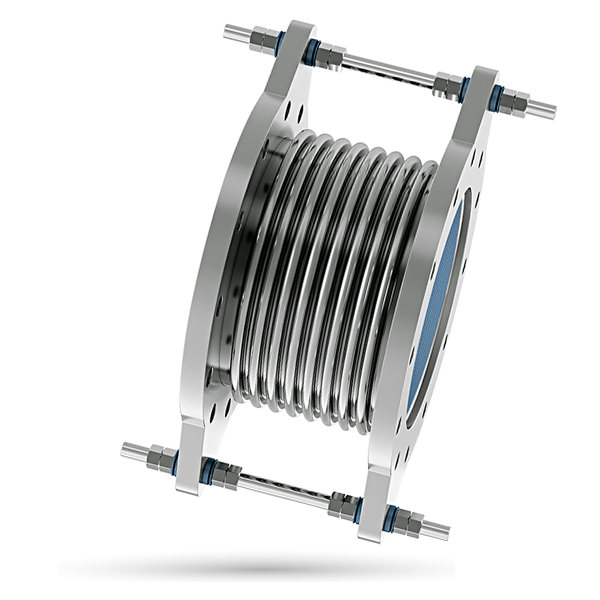

Metal expansion joints are pieces of equipment that perform a very important task, as they are able to withstand high pressures and temperatures in critical processes, often with hazardous or explosive fluids flowing through them at high temperatures.

Fabric expansion joints are used primarily in boilers, ventilation circuits, industrial ovens, cement factories and paper mills to absorb movements, vibrations and prevent stresses in piping systems with gases, air or steam at temperatures up to 1200 °C (2200 °F) and normal pressures below 0.35 kg/cm2 (5 psi).

We offer a wide range of special products for different requirements and levels of performance.

Within the typical life cycle of an installation, the expansion joint manufacturers supply teams during the assembly, maintenance, and replacement phases (black marks on the figure). The broad range of experience and knowledge possessed by BIKAR’s personnel allows them to provide support for customers in the most critical phases of an installation’s life cycle (blue marks). This allows the installations to be more profitable, durable, and efficient, while also eliminating unnecessary costs.

BIKAR has had a presence in the world of water for more than 20 years, using its knowledge to improve desalination plants and potable water pumping facilities.

The energy sector is one of the most demanding when it comes to quality of materials and control of the manufacturing process. BIKAR has a presence in nuclear power plants as well as in combined cycle power plants.

BIKAR responds to the all of the demands of this market with its expansion joints manufactured using special materials, for demanding environments: corrosive, extreme, explosive, high pressure (more than 50 bar – 725 psi), high-temperature (up to 1200 ºC -2200 ºF), and for any other required specifications.

BIKAR provides its experience and support to companies for their engineering, technical, maintenance, and production departments, in order to improve their results.

Equipment manufacturers typically incorporate expansion joints as accessories to their products. Collaboration with BIKAR allows manufacturers to make the market’s best materials available, improving their image in the sector while also providing their installations with maximum reliability.

BIKAR collaborates with large engineering firms around the world. In addition to supplying them with reliable, top- quality products, we also have knowledge of the entire life cycle of all of the existing types of expansion joints.

The highly corrosive processes and harsh demands of this type of industry require knowledge of high value-added materials and proven high-pressure and high-temperature designs.

The mining industry always requires the highest quality solutions. The processes are extremely demanding, and materials specifications must ensure chemical resistance to the fluids used in the washing process, and resistance to abrasion from moving solids.

At BIKAR, a manufacturer with over 40 years of experience and a presence in more than 45 countries, we supplied an expansion joint package for a water treatment plant in…

BIKAR designs and manufactures multiple wave expansion joints according to clients needs. These joints are designed to absorb large axial movements while ensuring the safety and efficiency of the piping…

Supply of an important package of expansion joints and dismantling joints for a desalination plant in the United Arab Emirates. This is a tailor-made project for one of the most…

As a company specialized in the design and manufacture of expansion joints, on this occasion we have successfully developed a large expansion joint for a critical customer in Qatar. It…

Supply of expansion joints designed and manufactured for an important pumping station located in Egypt. In this case, due to the movements specified by the client, a type of joint…

As we announced in February, Bikar Expansion Joints was in charge of a project in Bahrain for one of the most important Water and Energy clients in the country, consisting…

Bikar expansion joints makes official the second and last shipment for a desalination plant in Saudi Arabia. In this case it is a project in the extension phase. This project…

Bikar Expansion Joints collaborates with Euskalit in the spread of the European Week of Advanced Management. Our collaborators, called “Astezaleak”, have the mission of promoting these sessions, making visible their…

Sorry, this entry is only available in European Spanish.

As we were already anticipating at the beginning of the year, 2024 is full of news for Bikar Expansion Joints. We are pleased to inform you that we are moving…